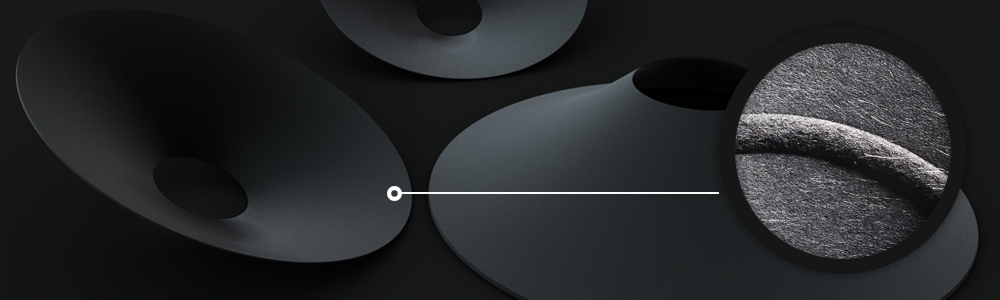

Paper Cones

Due to it’s ideal combination of low weight and excellent mechanical features (stiffness, damping) paper is still a material that is highly suitable for the production of loudspeaker cones. By means of special processes and materials DKM offers an appropriate solution for each of your applications.

1. Production of paper cones

- sieve inside or sieve outside

- pressed for improvement of fidelity

- air dryed to increase internal damping

- sizes up to 10 inches are produced in Germany, sizes larger than 10 inches are produced in UK

2. Materials of paper cones

- production in UK: hardest Blue Sig, standard material and soft material Mu and K2 or very hard special material SigX

- production in Germany: hard, black ST material, standard material and soft, damping materials V, DU, DS and special materials MA (Micra), NU

- for increase of strength spacing material is used (aramid fibre, carbon fibre, glass fibre, ...)

3. After treatment of paper cones

- hardening of cone neck or whole cone by painting

- water-repellent, bactericidal or fungicidal design

- complete immersion to raise internal damping

- coating to improve appearance and acoustics

- laminating with high-tech fabrics